Product

Contacts

Address:

No. 2 Qunying Road, Fushan District, Yantai, Shandong Province, China

E-mail:

Wechat / whatsapp / Skype:

+86 18254591008 (Grace)

+86 18865573253 (Howdy)

Telegram

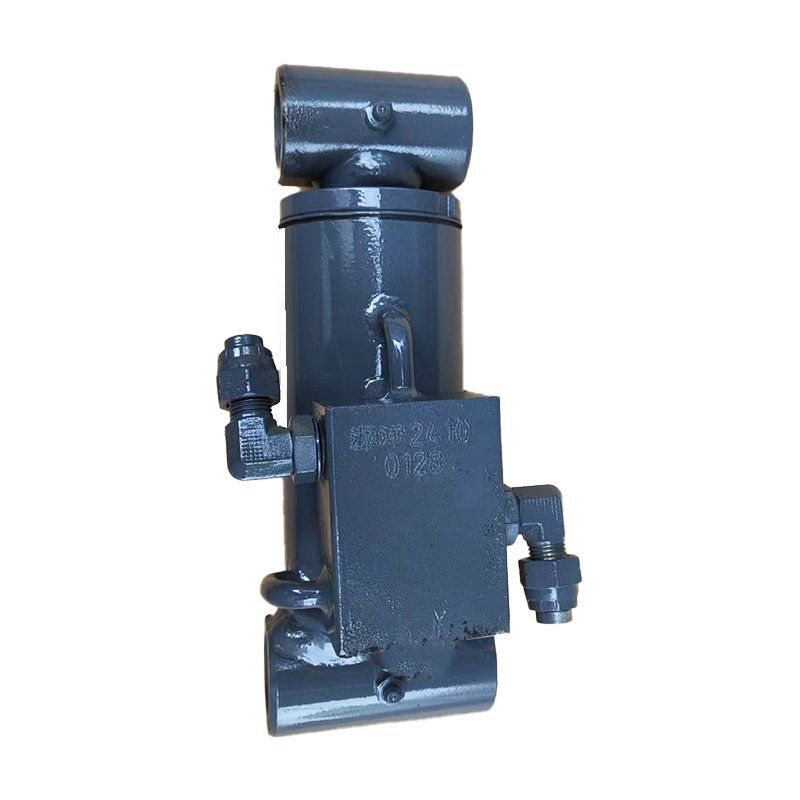

Cylinder for Excavator CLG920D,Ce bucket cylinder excavator Oem

- Product description

-

In the construction and earth - moving industries, the bucket cylinder excavator has emerged as a crucial piece of machinery that is changing the game.

The bucket cylinder is a key component of an excavator, playing a vital role in the digging and scooping functions. A well - designed bucket cylinder on an excavator can significantly enhance the machine's overall performance.

Modern bucket cylinder excavators are engineered with precision. These cylinders are made from high - quality materials, ensuring durability and reliability even in the harshest working conditions. They are built to withstand the high pressures and heavy loads associated with excavation work.

One of the main advantages of the bucket cylinder in an excavator is its ability to provide precise control. Operators can manipulate the bucket with great accuracy, whether it's digging a trench, scooping up loose soil, or handling heavy rocks. This precision not only improves the efficiency of the work but also reduces the risk of errors and accidents on the job site.

In terms of productivity, bucket cylinder excavators are unrivaled. The powerful force exerted by the bucket cylinder allows for quick and efficient digging. With a larger displacement bucket cylinder, excavators can move more earth in a shorter amount of time, saving both time and cost for construction projects.

Manufacturers are constantly innovating to improve bucket cylinder excavators. New technologies are being incorporated to enhance the smoothness of operation. For example, advanced hydraulic systems are used to ensure that the bucket moves fluidly, without jerks or sudden stops.

Another area of improvement is in the maintenance of these excavators. With better - designed bucket cylinders, maintenance intervals can be extended. Sealing technologies have been enhanced to prevent hydraulic fluid leakage, which can lead to costly repairs and downtime.

The versatility of bucket cylinder excavators is also remarkable. They can be used in a variety of projects, from small - scale landscaping jobs to large - scale infrastructure construction. Whether it's building a foundation for a skyscraper or creating a pond in a garden, the bucket cylinder excavator is up to the task.

As the demand for efficient and effective earth - moving solutions continues to grow, the bucket cylinder excavator will undoubtedly remain at the forefront of the construction and excavation industries, providing the power and precision needed to get the job done.

We produce various hydraulic cylinders, including non-standard hydraulic cylinders.

The information of hydraulic cylinders is listed in the following:

Renowned brand excavator hydraulic cylinder: excavator models are required.

Customized hydraulic cylinder: Hydraulic cylinder design drawings or measurement photos of each component are required, or samples should be delivered to China.

Application scenarios: excavator hydraulic cylinders, loader hydraulic cylinders, auto hydraulic cylinders, steel rolling mill hydraulic cylinders, ship hydraulic cylindersINTRODUCTION to CYLINDERS

The cyliner barral and piston rod are made of anti-freezing and wear-resistant materials.

Cyliner barral: 16 manganese

Piston rod: 42mcro

There are two types of oil seals: imported oil seals and Chinese oil seals (optional)

Paint: High quality paint will not peel off at low temperatures. You can choose the color of paint.Minimum order quantity: 1 piece

Packaging: carton/wooden (optional)Model Width front bushing Width rear bushing Internal diameter shaft Load capacity excavator Stroke Mini-hydraulic 28 64 20 2-3ton 168-203

Cylinders, being the core of the hydraulic system in the implementation of this component, have undeniable significance. Below is a detailed description of the cylinder, covering its definition, working principle, structural composition, operational characteristics, areas of application, development trends, and other aspects.

First, definition and overview

A cylinder, known as a hydraulic cylinder, is a device for converting hydraulic energy into mechanical energy. It uses liquid pressure to create force and motion, through controlling the liquid in and out and the flow, to achieve linear reciprocating motion or oscillatory motion. Cylinders are widely used in various types of mechanical equipment, being an important part of the hydraulic system.Secondly, the working principle

The working principle of the cylinder is based on Pascal's principle, that is, when a liquid transmits pressure in a closed vessel, the pressure is the same everywhere. When oil enters the cylinder barrel through the cylinder's inlet, due to the incompressibility of the liquid, the oil creates a certain pressure in the cylinder. This pressure is transmitted to the working parts through the piston, creating force and motion. The piston of the cylinder can perform linear reciprocating motion, with the output linear displacement being limited, but various working modes can be achieved by controlling the flow of liquid into and out of the cylinder.In particular, the working process of the oil cylinder includes the following stages:

Oil intake stage: oil enters one side of the cylinder barrel through the inlet, resulting in a certain pressure on the piston, which pushes the piston to the other side.

Working stage: the piston pushes the working parts, transmitting force and performing work.

Oil return stage: when it is necessary to stop or change the direction of the piston movement, oil flows out of the cylinder barrel through the oil return hole, so that the pressure on the piston decreases or disappears, thus realizing the stop or reverse movement of the piston.Structure

The structure of the cylinder is complex and precise, mainly consisting of the following parts:Cylinder barrel and cylinder cover: the cylinder barrel is the main part of the cylinder, which is usually made of high-quality seamless steel pipe. The hole is finely processed to achieve a high degree of finish, reduce friction during movement, and extend the service life of the seals. The cylinder cover is used to close one end of the cylinder barrel and form a closed chamber with the cylinder barrel.

Piston and rod: the piston is a key component of the cylinder, which closely fits the inner wall of the cylinder through seals. The piston rod is connected to the piston and transmits the movement of the piston to external working organs. Pistons and rods are most often made of cast iron or steel and undergo special treatment to enhance their wear resistance and corrosion resistance.

Seals: Seals are used to prevent hydraulic fluid leakage and maintain pressure in the system. Common seals include O-rings, Y-shaped seals, V-shaped seals, etc. These seals are usually made of high-performance materials that have good wear resistance, corrosion resistance, and high-temperature resistance.

Damping device and exhaust device: The damping device is used to reduce impact load and vibration when the piston moves to the end, to protect the cylinder and working parts from damage. The exhaust device is used to remove air and impurities in the cylinder to ensure the normal operation of the cylinder.

In addition, the cylinder may include some auxiliary components, such as an oil port, dust protection device, etc., these parts do not directly participate in the working process of the cylinder, but play an important role in improving the performance and reliability of the cylinder.

Fourthly, operational characteristicsThe oil cylinder has the following important operational characteristics: high specific power: compared to a cylinder, the oil cylinder can produce greater power, suitable for cases requiring high output power. Smoothness: the movement of the cylinder is smooth, with a fast response speed, allowing for precise control of position and speed. Reliability: the design of the cylinder is relatively simple, it is easy to maintain, and the hydraulic transmission is self-lubricating, which reduces wear and failures. Adaptability: the cylinder can be adjusted according to various working requirements, such as changing the diameter of the cylinder, stroke, and other parameters to adapt to different working conditions and work content. Safety: the cylinder is equipped with a whole range of protective devices, such as a pressure maintenance safety device, pressure relief valve, etc., to ensure safe operation under overloads or abnormal conditions.

Areas of application

The areas of application of oil cylinders are wide and diverse, covering many industries such as machine engineering, automotive, metallurgy, chemical industry, construction, environmental protection, electric power, and so on. In machine engineering, cylinders are widely used in various mechanical devices, such as stamping machines, shears, hydraulic presses, shaft pulling machines, etc.; in the automotive industry, cylinders play an important role in the braking system, transmission, and suspension; in the metallurgy industry, cylinders are used in stamping presses, shears, rolling mills, bending machines, etc.; in the chemical industry, cylinders are used in oil, chemical processes, and equipment; in the construction industry, cylinders are used in oil, chemical processes, and equipment; in the environmental protection industry, oil cylinders are used in wastewater treatment, seawater desalination, and other equipment; in electric power, oil cylinders are used in hydroelectric power stations, gas turbines, nuclear power plants, and other large-scale equipment.

Production capacity

The company has a modern production workshop and advanced manufacturing equipment, which provides a reliable guarantee of product quality and production efficiency. We manage production in strict accordance with the ISO9001 quality management system to ensure that each link meets quality standards. At the same time, we also have advanced testing equipment and strict quality control processes to ensure product standardization.

Research and development capabilities:

The company has established a good reputation in the field of scientific research, has a high-quality and professional R&D team, and holds a number of invention patents. Team members possess rich industry experience and professional knowledge and are committed to technological innovation and modernization of excavators and cylindrical equipment.

Keyword:

Cylinder for Excavator CLG920D,Ce bucket cylinder excavator Oem

FAQ

The content of the excavator is as follows

Question 1: The warranty period of the excavator

Answer: One year or 2,000 hours

Question 2: Can replacement parts be found in the customer's country?

Answer: Yes. (We provide some small accessories for free.)

Question 3: Can customized services be provided?

Answer: Yes. (We can offer color customization and logo customization.)

Question 4: What kind of engine is adopted?

Answer: Chinese engines or imported engines (as per customer requirements)

Engines are classified into single-cylinder engines, two-cylinder engines and three-cylinder engines

Question 5: What are the modes of transportation?

Answer: Ocean transportation, railway transportation and road transportation

For ocean transportation, we are not responsible for customs clearance and tariffs. We only handle delivering the goods to ports (such as the Port of St. Petersburg and the Port of Vladivostok).

For railway and road transportation, we are responsible for customs clearance and tariffs. If the customer needs it, it can be delivered directly to the door

The contents of the hydraulic cylinder are as follows

Question 6: The materials that need to be provided by the customer before making a quotation

Answer: Hydraulic cylinder number/parameter photo/Hydraulic cylinder floor plan (It is best to provide two sets of materials)

3D design drawings of hydraulic cylinders can be made (only design drawings are required, but an additional charge applies. If you place an order for purchase, it can be free of charge).

Question 7: Can customized services be provided?

Answer: Yes. (We can offer color customization and logo customization.)

Question 8:

Payment Method:

Question 9: Transaction process

We offer quotations. The customer pays a 30% advance payment and the factory arranges for production. After the factory production is completed, we will provide a video for the customer to confirm the status of the goods. Once confirmed to be correct, the customer will pay 70% of the balance. After the factory receives the payment for goods, we will deliver the goods.

Question 10: Payment Account

Company payment: If payment is made through a company account, we can provide a company account (VTB account).

If it is an individual payment, we can provide a personal account (only accepting rubles).

The time for the funds to arrive: generally, it is 1 to 3 days

Consultation