Product

Contacts

Address:

No. 2 Qunying Road, Fushan District, Yantai, Shandong Province, China

E-mail:

Wechat / whatsapp / Skype:

+86 18254591008 (Grace)

+86 18865573253 (Howdy)

Telegram

Excavator DX1000HD 100 Tons

- Product description

-

Technical Parameter

Model DX1000HD

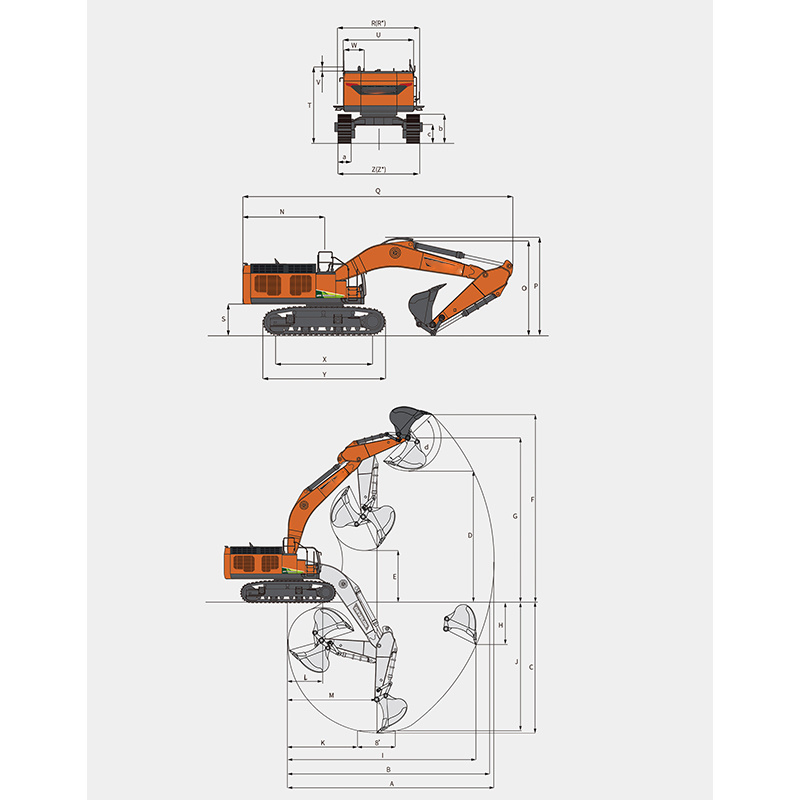

Outline Dimension

Boom

(mm)

7,250

Arm

(mm)

2,900

Bucket capacity

(m3)

5.4~7.2

Rear swing radius

N

(mm)

4,565

Transport height (boom)

O

(mm)

5,090

Transport height (cable)

P

(mm)

5,150

Transport length

Q

(mm)

13,800

Transport width (standard configuration)

R

(mm)

3,732

Transport width (narrow)

R*

(mm)

-

Minimum counterweight ground clearance

S

(mm)

1,615

Height (cab)

T

(mm)

3,615

Upper body width

U

(mm)

3,410

Cab width

W

(mm)

1,010

Center distance between guide wheel and drive wheel

X

(mm)

5,100

Track length

Y

(mm)

6,341

Lower body width (standard)

Z

(mm)

3,440/4,200*

Lower body width (narrow)

Z*

(mm)

-

Track width

a

(mm)

650

Track height**

b

(mm)

1,350

Minimum ground clearance

c

(mm)

860

Scope of Work

Maximum digging range

A

(mm)

12,430

Maximum digging range (above ground)

B

(mm)

12,110

Maximum digging depth

C

(mm)

7,260

Maximum dumping height

D

(mm)

8,100

Minimum dumping height

E

(mm)

3,910

Maximum digging height

F

(mm)

12,425

Maximum bucket pin height

G

(mm)

10,515

Maximum vertical digging depth

H

(mm)

2,965

Maximum vertical digging distance

I

(mm)

10,995

Maximum 8 feet digging depth

J

(mm)

7,110

Minimum 8 feet digging distance

K

(mm)

4,410

Minimum digging distance

L

(mm)

1,970

Minimum swing radius

M

(mm)

5,345

Bucket rotary Angle

d

(°)

145.3

Main Specification

Engine

Model

Perkins 2806J

Discharge

Stage 4

Power

469kw/2, 000rpm

Reprocessing

DPF+SCR

Hydraulic cylinder

Both the piston cylinder and cylinder body are made of high-strength steel, and all oil cylinders are designed with Shock Absorber to ensure that there is no impact or vibration during operation

Boom

2- 215×1 50×1, 910 mm

Arm

1-2 40×1 70× 2,020 mm

Bucket

1-2 25×1 60×1, 530 mm

Traveling gear

Each walking device is equipped with a high torque axial plunger motor, which is then reduced by a planetary gear system to increase traction. The excavator can be moved forward or backward smoothly by two pedals or walking control rods.

Speed (high/low)

4.5/2.8km/hr

Maximum traction force

78.7/ 47.9 ton

Climbing slopes

35°

Add Capacity

Fuel tank

1,100 L

Engine oil

6 5 L

Cooling system (water tank)

100 L

Travel gear

2× 15 L

Swing gear

2×8L

Hydraulic oil tank

880 L

Maximum Digging Force (ISO)

Arm length

2,900 mm

Bucket length

5.4~7.2m³

Arm digging force/ton

[SAE]40.3,[ISO]40.8

Bucket digging force/ton

[SAE]44.8,[ISO]48.2

Hydraulic System

The core of the system is EPOSTM(Electronic Power Optimization System). It can optimize system efficiency under any working conditions and minimize fuel consumption. New EPOSTM engine control unit is connected to the engine via a data transmission line, coordinating the operation of the engine and hydraulic system. The hydraulic system supports both independent and combined operation modes.

· Two walking speeds can ensure both walking torque and walking speed

· The interactive sensor control main pump control system can save fuel

· Automatic speed reduction system

· Two operating modes, two power modes

· The flow of the optional equipment pipeline can be controlled by one button

· Computer aided pump power control

Main Pump

Type

Series, axial piston

Maximum flow

3×5 23L/min

Pioneer Pump

Type

Gear pump

Maximum flow

60L/min

Working pressure

Hydraulic circuit of working device

377kg/cm²(37Mpa)

Travel the hydraulic circuit

375kg/cm²(36.8Mpa)

Rotary hydraulic circuit

300kg/cm²(29.4Mpa)

Chassis

A robust chassis, all welded structures are designed to limit stress concentration. High-strength materials are selected to ensure durability. The side chassis is directly welded to the X-frame. Heavy wheels, idler wheels, and sprockets all use floating oil seals. The three-toothed track plates are treated with induction quenching to improve wear resistance, and the connecting pins are also quenched. Hydraulic travel dampers can filter out most of the vibrations during movement.

Upper support wheel

Two by three

Lower the heavy wheel

2 × 9

Tread shoe

2 × 51

Total length of track

6,341 mm

Turning System

The rotary torque is high, equipped with wet planetary gear reducer and axial piston motor, through wet oil cylinder without impact vibration. Single row, shear type ball bearing and internal stress quenched gear to complete the rotary action.

Maximum swing speed

6.1 rpm

Maximum swing torque

31,850 kgf.m(251kN.m)

Track (Three-Tooth Track Plate)

Track shoe width

650mm (standard)

Operate the weight

97.9 ton

Grounding pressure

1. 37kg/cm²

Production capacity

The company has a modern production workshop and advanced manufacturing equipment, which provides a reliable guarantee of product quality and production efficiency. We manage production in strict accordance with the ISO9001 quality management system to ensure that each link meets quality standards. At the same time, we also have advanced testing equipment and strict quality control processes to ensure product standardization.

Research and development capabilities:

The company has established a good reputation in the field of scientific research, has a high-quality and professional R&D team, and holds a number of invention patents. Team members possess rich industry experience and professional knowledge and are committed to technological innovation and modernization of excavators and cylindrical equipment.

Keyword:

Excavator DX1000HD 100 Tons

FAQ

The content of the excavator is as follows

Question 1: The warranty period of the excavator

Answer: One year or 2,000 hours

Question 2: Can replacement parts be found in the customer's country?

Answer: Yes. (We provide some small accessories for free.)

Question 3: Can customized services be provided?

Answer: Yes. (We can offer color customization and logo customization.)

Question 4: What kind of engine is adopted?

Answer: Chinese engines or imported engines (as per customer requirements)

Engines are classified into single-cylinder engines, two-cylinder engines and three-cylinder engines

Question 5: What are the modes of transportation?

Answer: Ocean transportation, railway transportation and road transportation

For ocean transportation, we are not responsible for customs clearance and tariffs. We only handle delivering the goods to ports (such as the Port of St. Petersburg and the Port of Vladivostok).

For railway and road transportation, we are responsible for customs clearance and tariffs. If the customer needs it, it can be delivered directly to the door

The contents of the hydraulic cylinder are as follows

Question 6: The materials that need to be provided by the customer before making a quotation

Answer: Hydraulic cylinder number/parameter photo/Hydraulic cylinder floor plan (It is best to provide two sets of materials)

3D design drawings of hydraulic cylinders can be made (only design drawings are required, but an additional charge applies. If you place an order for purchase, it can be free of charge).

Question 7: Can customized services be provided?

Answer: Yes. (We can offer color customization and logo customization.)

Question 8:

Payment Method:

Question 9: Transaction process

We offer quotations. The customer pays a 30% advance payment and the factory arranges for production. After the factory production is completed, we will provide a video for the customer to confirm the status of the goods. Once confirmed to be correct, the customer will pay 70% of the balance. After the factory receives the payment for goods, we will deliver the goods.

Question 10: Payment Account

Company payment: If payment is made through a company account, we can provide a company account (VTB account).

If it is an individual payment, we can provide a personal account (only accepting rubles).

The time for the funds to arrive: generally, it is 1 to 3 days

Consultation